Now Reading: Shaping Tomorrow with 3D Printing

-

01

Shaping Tomorrow with 3D Printing

Shaping Tomorrow with 3D Printing

3D Printing Manufacturing the Future

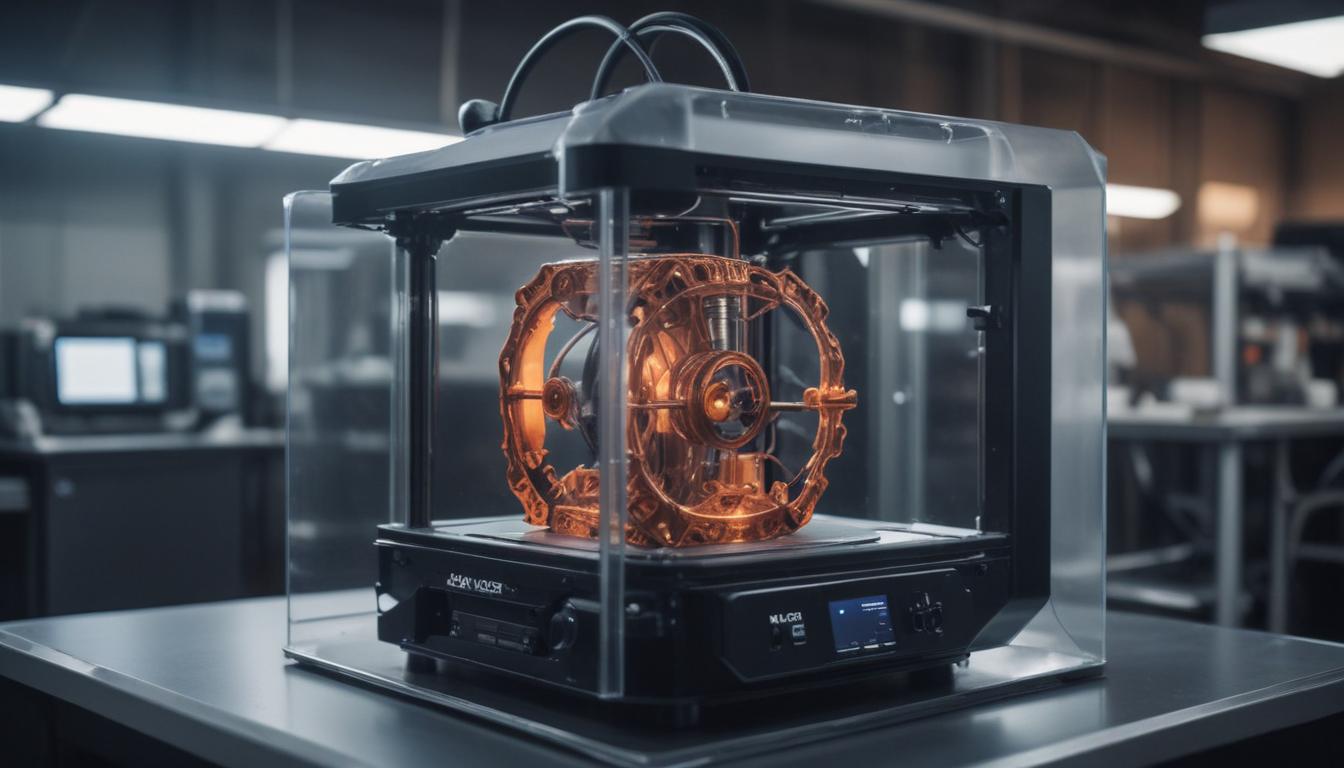

Have you ever heard the term “3D printing” and pictured a complex, whirring machine from a science fiction movie, creating objects out of thin air? You’re not alone. For many, this technology feels distant, complicated, and reserved for high-tech labs or mega-corporations. You might wonder what it really is and, more importantly, how it could possibly affect your life. The truth is, this revolutionary technology is far more accessible and impactful than you think. It’s not magic; it’s a new way of making things, and it’s already quietly reshaping our world, from the healthcare you receive to the cars you drive. This guide will demystify 3D printing, showing you exactly how it works and why it represents a fundamental shift in manufacturing.

What Exactly Is 3D Printing

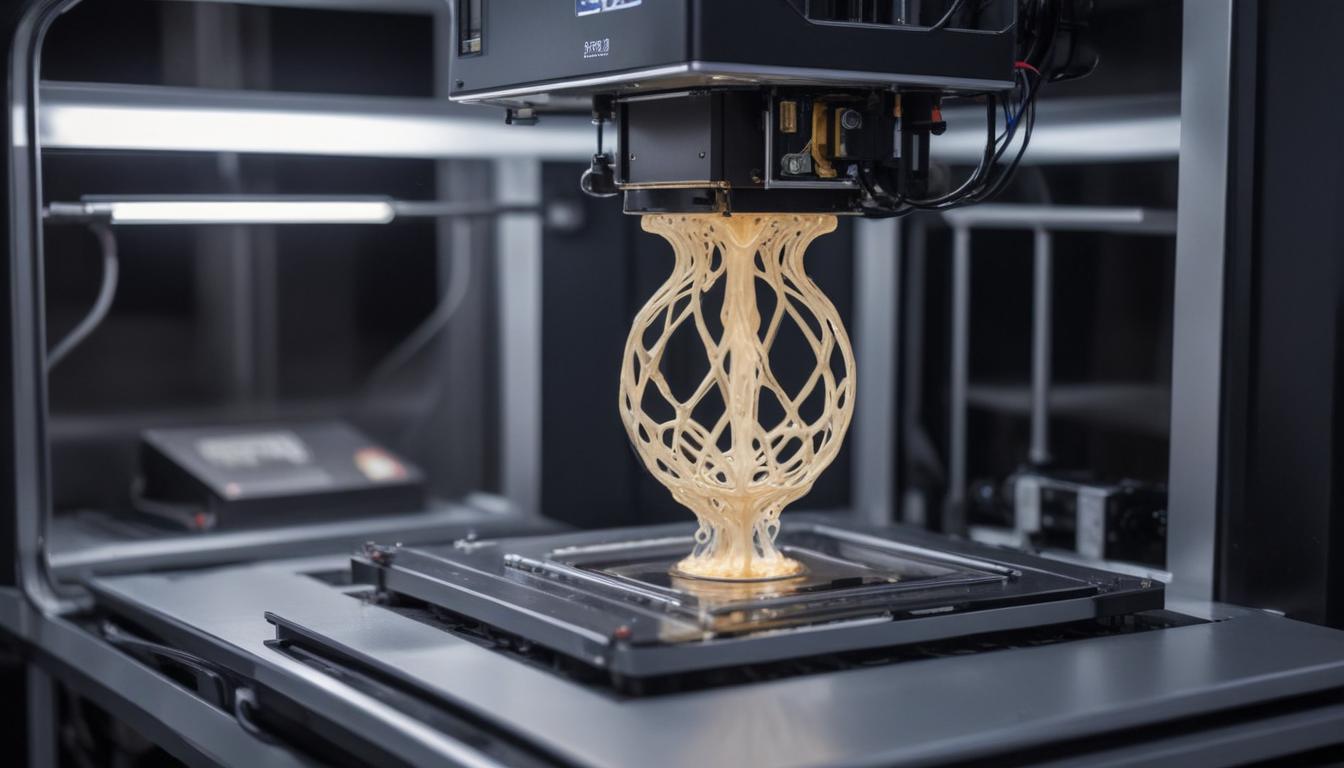

At its core, 3D printing, also known as additive manufacturing, is the process of creating a three-dimensional object from a digital file. Think of it as the opposite of traditional sculpting. A sculptor starts with a block of stone and carves away material to reveal the statue within—this is called subtractive manufacturing. 3D printing does the reverse. It builds an object from the ground up, adding one super-thin layer of material at a time until the final form is complete. It’s like building a complex Lego model, but instead of snapping bricks together, a machine precisely deposits or fuses material according to a digital blueprint.

The process begins with a digital design, often created using Computer-Aided Design (CAD) software. This digital model is then “sliced” into hundreds or even thousands of horizontal layers by another piece of software. The 3D printer reads this sliced file and begins its work, methodically building the object layer by layer. While plastic filaments are the most common material for hobbyists, industrial printers can use a vast range of materials, including metals like titanium and aluminum, flexible resins, carbon fiber composites, and even biocompatible materials for medical use. This versatility is a key reason for its widespread adoption.

How 3D Printing is Changing Industries Today

Far from being a futuristic concept, additive manufacturing is already a powerful tool that is solving real-world problems and creating new opportunities across countless sectors. Its ability to produce highly complex, customized parts quickly and with less waste is disrupting traditional manufacturing pipelines. Companies are moving beyond using it just for prototypes and are now printing final, functional parts that are lighter, stronger, and more efficient than their traditionally made counterparts.

Revolutionizing Healthcare

Perhaps nowhere is the impact of 3D printing more personal and profound than in medicine. Doctors and engineers are using this technology to create custom-fit prosthetic limbs, dental implants, and surgical guides that are perfectly tailored to a patient’s unique anatomy. Imagine a knee replacement designed not for the average person, but specifically for your body, leading to better comfort and a faster recovery. This level of personalization was once impossibly expensive, but 3D printing makes it a reality.

Furthermore, surgeons can now 3D print exact replicas of a patient’s organs before a complex operation. This allows them to plan their approach, anticipate challenges, and even practice the surgery on a realistic model, significantly reducing risks in the operating room. Looking ahead, the field of bioprinting is even experimenting with printing living tissues and, one day, entire organs for transplantation, holding the potential to eliminate organ donor waiting lists forever.

Transforming Aerospace and Automotive

In industries where weight and performance are critical, 3D printing is a game-changer. Aerospace and automotive engineers use it to create lightweight components with intricate internal lattice structures that are impossible to make with conventional methods. For an airplane, reducing weight by even a small amount can translate into massive fuel savings over its lifetime. Major companies are already printing parts like fuel nozzles and brackets that are not only lighter but also stronger and more reliable.

This technology also drastically speeds up the innovation cycle. Instead of waiting weeks or months for a new part to be tooled and manufactured for testing, an engineer can design it in the morning and have a physical prototype to test by the afternoon. This rapid prototyping allows for faster iteration and better final products. Moreover, it enables on-demand manufacturing of spare parts, reducing the need for massive warehouses and allowing for the creation of obsolete parts for classic cars or older machinery.

The Future is Additive What’s Next for 3D Printing

The journey of 3D printing is just beginning. As the technology becomes faster, cheaper, and capable of handling a wider array of materials, its influence will continue to grow. We are moving toward a future of mass customization, where the products we buy, from shoes to furniture, can be perfectly tailored to our individual needs and preferences. Manufacturing will become more decentralized, shifting from giant overseas factories to smaller, local hubs that can print products on demand, strengthening local economies and reducing the environmental impact of shipping.

We are also on the cusp of even more advanced applications. Scientists are developing “4D printing,” where printed objects can change shape or self-assemble over time when exposed to stimuli like heat or water. Construction companies are experimenting with massive 3D printers that can build entire houses in a fraction of the time and cost. From printing sustainable food sources to creating components in the zero-gravity environment of space, the possibilities are limited only by our imagination. 3D printing is not just a new tool; it’s a new way of thinking, creating, and building the world around us.